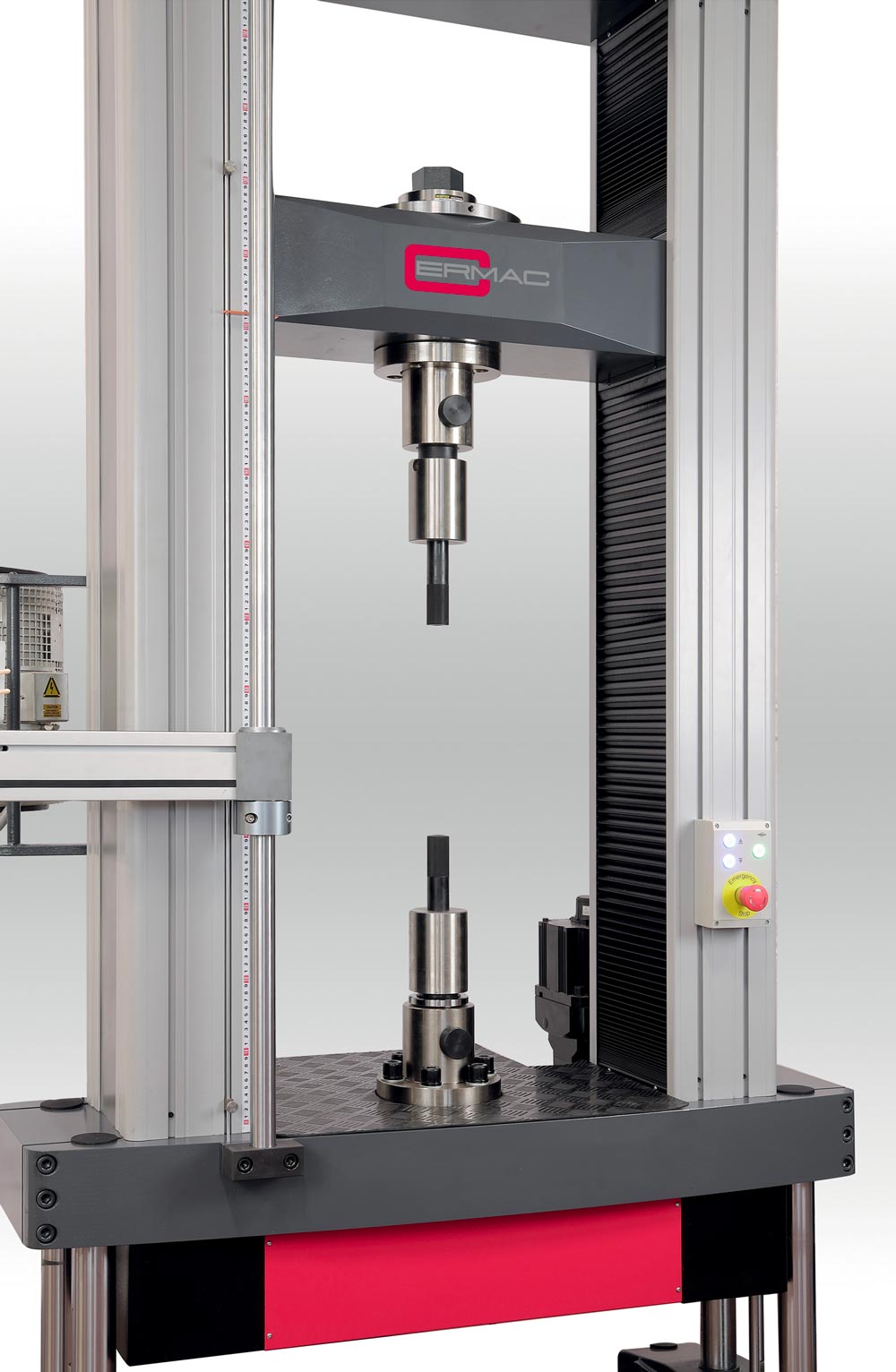

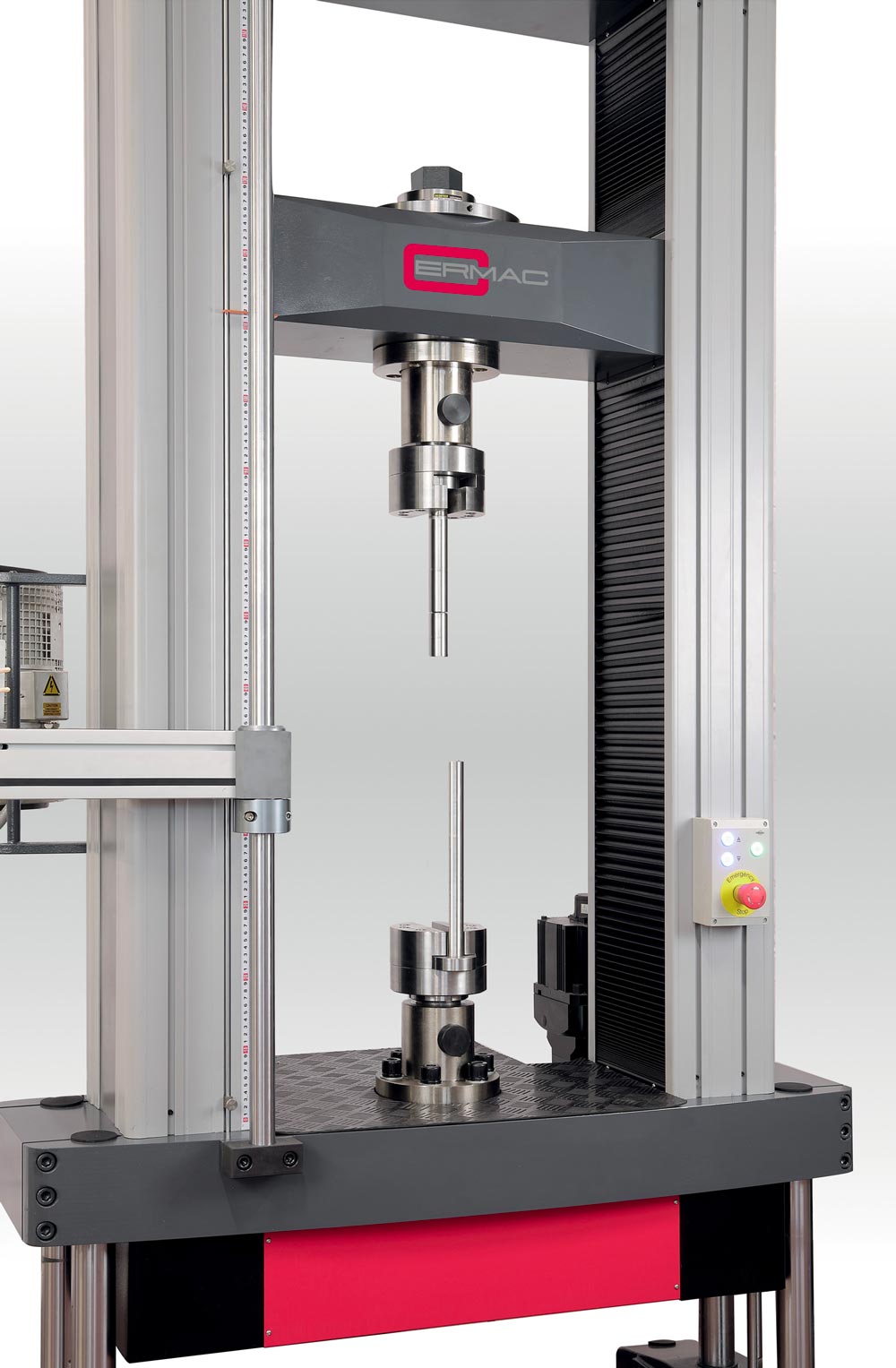

Universal testing machines suitable for every need

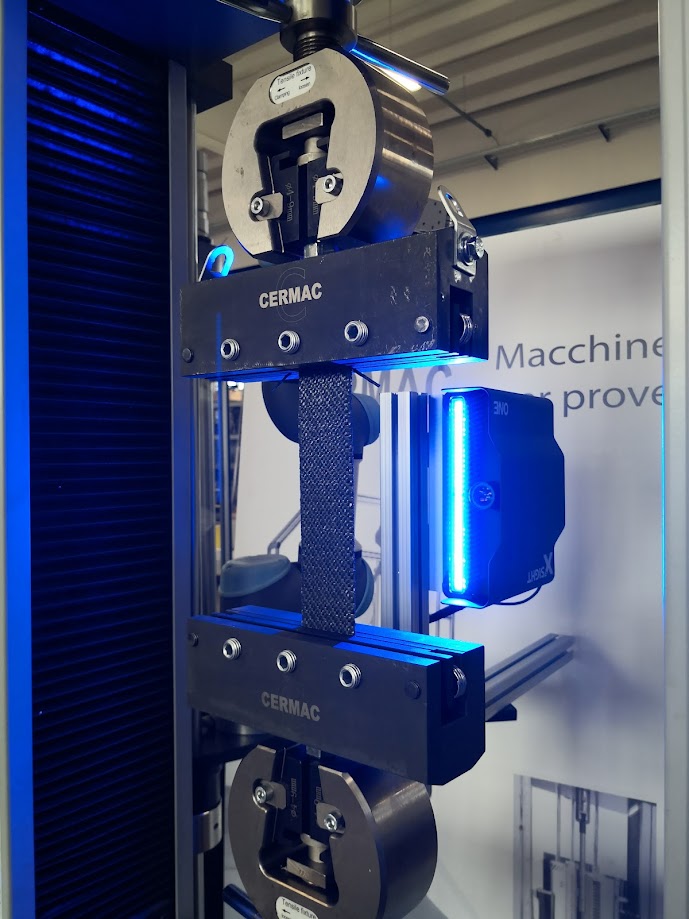

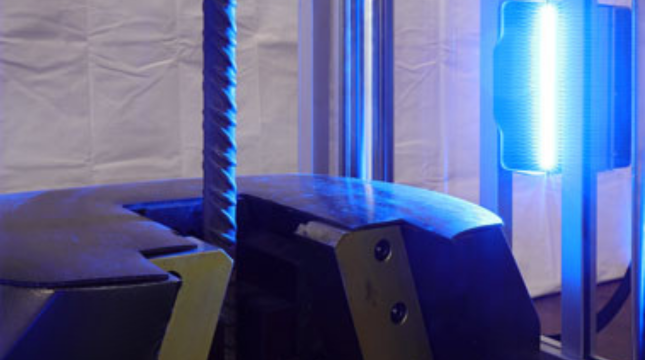

UTM-E SERIES

Universal testing machine, computerized, suitable to perform tensile, compression, flexure and bending tests.

- Electromechanical universal testing machine.

- Automatic, servocontrolled, coomputer controlled.

- Digitally driven brushless motor for precise control of the test speed.

- High accuracy load cell with option of tool that allows the verification and correction of the axial load application.

- Double test space.

- TestingXE Computerized Control System.

- Extremely quick and easy test accessories change.

- Availability of many optional accessories to perform any type of test.

TECHNICAL FEATURES

| Models | UTM 50E / UTM 100E |

UTM 200E |

UTM 300E |

| Load capacity | 50 – 100 kN | 200 kN | 300 kN |

| Accuracy | Class 1 ( or better) from 1 % of full scale ISO-7500 | ||

| Speed range | from 0.001 to 250 mm/min | ||

| Maximum stroke | 800 mm | 800 mm | 800 mm |

| Vertical test area space | 550 mm | 650 mm | 650 mm |

| Test area width | 420 mm | 650 mm | 650 mm |

| Frame dimensions | 1050 x 620 x 2050 mm | 1250 x 720 x 2300 mm | 1250 x 720 x 2300 mm |

| Weight of the frame | 850 kg | 1650 kg | 1850 kg |

| Power supply | 2.5 kW 400 VAC / 50 Hz / 3 phases (5 poles) | ||

| ADC Converter | 24 bit / 1 kHz | ||

MAIN REFERENCE STANDARDS

| Tensile test on steels | ISO 6892-1, ASTM E8, ASTM A370, ISO 15630 |

| High temperature tensile test | ASTM E21, ISO 6892-2, ISO 6892-3 |

| Tensile test on alloy | ASTM B348, ASTM B557 |

| Tensile test on soldered metals | ISO 4136, ISO 5178, ISO 5173 |

| Tensile test on castings and forgings | ISO 3266, EN 818-X, EN 1677-X |

| Bending test on metals | ISO 7438, ISO 5173, ASTM E190, ASTM E290 |

TESTINGXE CONTROL SYSTEM

Features

The Computerized Testing Control System consists of a latest generation data logger, equipped with a microprocessor electronic module with TCP / IP network interface, capable of managing analog and digital signal inputs and outputs, using firmware and software developed by our IT department. . All the signals relating to the physical quantities coming from the electronic sensors of the machine (load cell and digital encoders), as well as those of the electronic strain gauges applied on the sample for direct measurements of the deformations of the material, are acquired in real time by means of an ADC converter with resolution up to 24 bit and speed up to 1 kHz. The Software Testing, in particular, allows the introduction of the necessary test parameters, through insertion masks that can be adapted to the specific needs of the operator, to then proceed with the execution and display in real time of each test parameter. The results are acquired and stored in a database in a totally automatic way, so as to ensure their easy traceability for subsequent processing. Thanks to the test modules that can be completely customized by the user, it is possible to print graphically accurate documents, which can be used for both certification and archiving of internal minutes. The database can be shared on the network and the software can be used simultaneously on different PCs allowing the display and processing of test data from different workstations, with automatic and advanced functions for loading data and exporting results in accordance with the requests relating to Industry 4.0 initiatives.

WIDE RANGE OF OPTIONAL TEST ACCESSORIES

Threaded specimens

Shoulder heads

Hot tensile tests

Manual or pneumatic grips

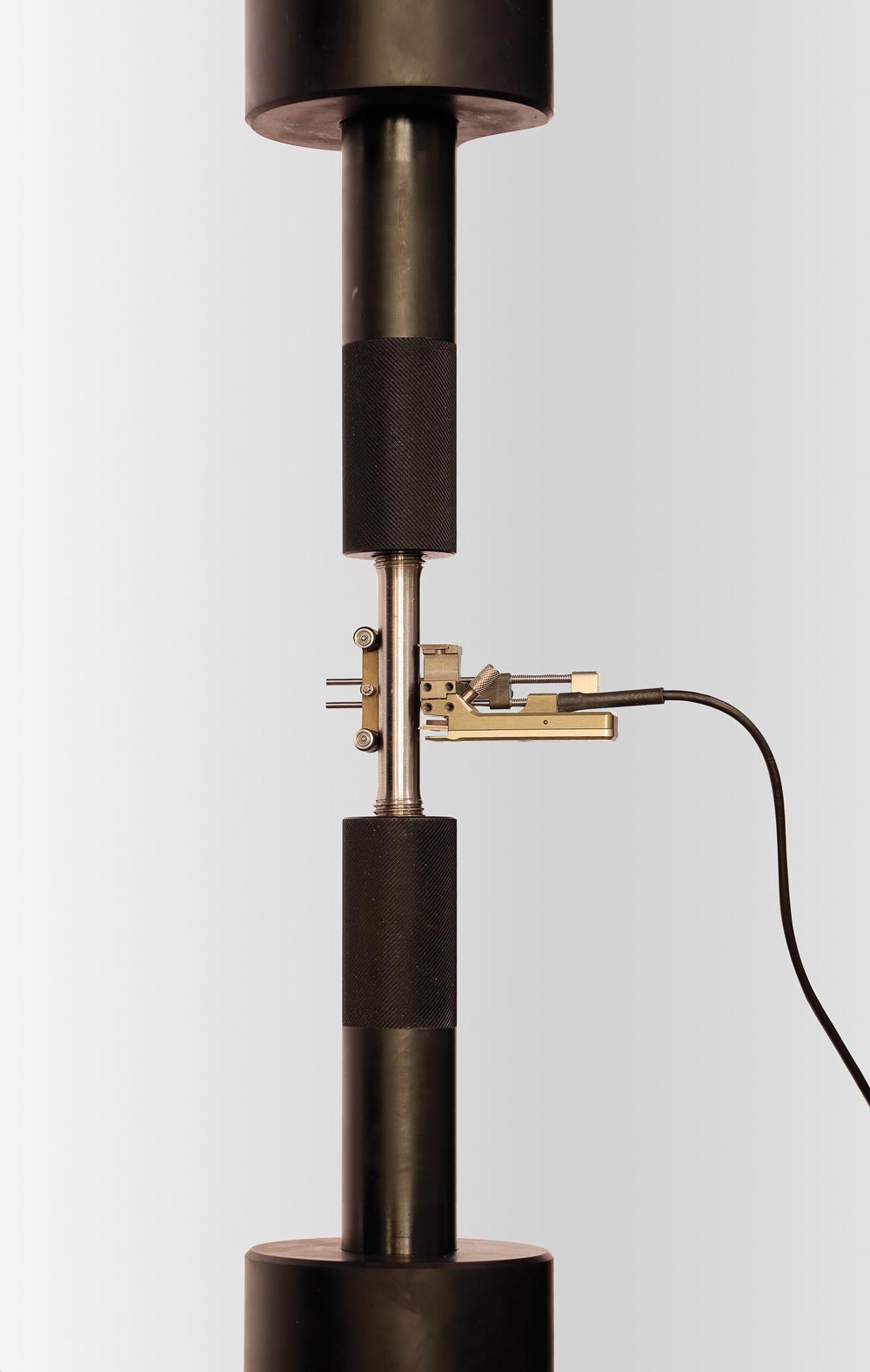

ELECTRONIC EXTENSOMETERS

Standard electronic clip-on gage

Simple strument suitable for Rp and Elastic Modulus values measurement

Miniaturized electronic clip-on gage

Simple instrument suitable for Rp and Elastic Modulus values measurement. Specific for samples and small spaces

Full automatic and motorized extensometer

Motorized, automatic instrument, suitable for values measuring of Rp, A, Agt and Elastic Modulus

APPLICATIONS AND NEWS

Breaking load and tensile strenght

Tensile Strength Tensile strength is a fundamental parameter of the mechanical properties of materials and identifies the ability of a material to resist tension before breaking. This characteristic is important for materials engineering, for the design of mechanical components and for ensuring the safety and reliability of products in different sectors. Characteristics and importance Tensile […]

ASTM A370: Standard for the testing of elasticity, strength, and elongation of metals

Introduction to ASTM A370 Standard ASTM A370 is a fundamental standard in metallic materials testing, focusing on the determination of elasticity, strength, elongation and cross-section reduction properties. This standard is widely used in various industries, including aerospace, automotive and engineering, to ensure that metallic materials meet specific quality and safety criteria. Testing methods according to […]

Yield Strength: Fundamentals and Applications

Yield strength is an important parameter in engineering materials, indicating the stress limit beyond which a material begins to deform plastically, maintaining permanent changes rather than returning to its original shape once the applied load is removed. This property is fundamental to the design and selection of materials in a variety of industrial applications, from […]

DIN EN ISO 898-2: mechanical properties and specifications for testing steel nuts

Overview of DIN EN ISO 898-2 The DIN EN ISO 898-2 standard establishes rigorous requirements for testing steel nuts and other ferrous materials. This standard is essential in the metallurgical industry to ensure the safety and reliability of components used in a wide range of engineering applications. Characteristics of tested materials Materials tested according to […]