The tensile test is a test of particular importance because it defines the so-called characterisation of a material in order to assess its main characteristics with a view to making the most of them. Often known under the term axial tensile test, it consists of a sample of standardised dimensions being subjected to an increasing uniaxial load in order to measure when yielding and breaking of the material occurs. The corresponding load values are used to define the suitability of the material for the intended use.

To perform a tensile test correctly, it is necessary to have a specially designed machine that allows a load to be applied to detect the desired characteristics.

How the tensile test is carried out

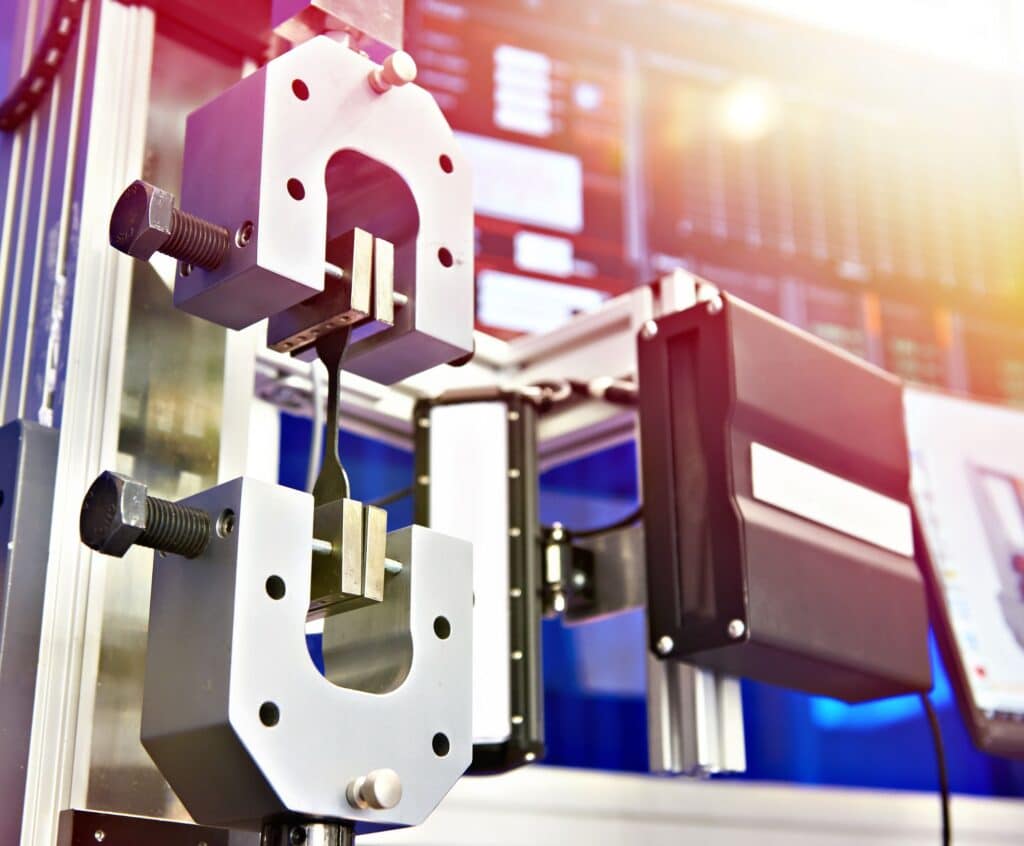

To perform the tensile test on a sample of material, the dimensions of which are set by standards such as UNI, EN and ASTM, and to measure its main characteristics, a special machine is used to apply the load. The test is started with a zero load and then gradually increased until the specimen in question breaks. The test is represented by means of a graph developed on a Cartesian axis system, the function of which is called the tensile curve. On the y-axis are the load values applied by the machine and on the x-axis the elongation of the test specimen. The same curve is then processed to obtain the elasticity curve of the material. From a practical point of view, the test involves the specimen being fixed on the two grips in a vertical position. This might appear to be of secondary importance, but in reality it is essential so that the force of gravity does not affect the test result, and it is also essential that the grips of the machine do not affect the machined part of the sample in any way. Thanks to sophisticated control electronics, a constant speed is set on the moving crossbar of the machine, thus creating a load that subjects the material to a strain. The intensity of this load is increased gradually over time until breakage occurs. In order to obtain the useful data for processing the tensile curve, it is necessary for the machine to have a load cell by means of which the force applied to the sample can be measured at all times and a strain gauge for measuring the deformation. These two values are basically the ones that are entered into the Cartesian axis system to obtain the tensile curve.

What is obtained from the tensile test

Thanks to the tensile test performed using a special machine, it is possible to obtain very important data relating to mechanical strength such as the maximum load (Rm), Young’s modulus or modulus of elasticity (E), unit yield strength (Rp), percentage elongation (A) and percentage reduction of area (Z). The most interesting aspect for engineers and those dealing with materials is the analysis of the tensile curve from which many considerations can be made about the material in question. For example, it is possible to know the material’s behaviour from an elastic point of view, and thus the possible deformation to which it will be subjected when subjected to a certain load. Deformation can be of various types, so we will speak of linear elastic deformation and non-linear plastic deformation. Yield strength represents the limit of elastic behaviour and determines the load from which the plastic deformation of the sample begins. As long as there is elastic deformation, the material returns to its initial characteristics when the load is removed, whereas when the behaviour is plastic, the deformation remains permanently applied. When the maximum value of the curve is reached, there will be reduction of area, i.e. localised deformation, and finally rupture.

The machines to perform the tensile test

There are various machines that allow the characteristics of a material to be assessed in detail in order to make the best use of it. The UTM-E series offered on the market by Cermac is a testing machine that, suitably equipped, can perform the tensile test at high temperatures. The test is completely managed with the appropriate software control panel and is fully servo-controlled. Operation is based on a digitally-driven brushless motor for extremely precise speed control and has a load cell that allows constant measurement of the applied load. Other features include a computerised control system, simplicity and speed in changing the various test accessories, and a 3-zone independent furnace for use up to 1000°C.

Alternatively, you may consider the UTM-H series. This is a universal testing machine that allows not only tensile but also compressive and flexural testing of high-strength specimens. In this case we are talking about a hydraulically-operated device and with a double-acting actuator driven by a servo-valve and serviced by a hydraulic unit, the noise level is very low. The models available can develop loads of 600 KN, 1000 KN and 2000 KN. The manufacturer also emphasises that this type of product has been developed above all to be able to carry out tests on samples such as smooth and improved adhesion bars. This machine also has an electronic control system with a 24-bit ADC converter.

Should load tests be carried out at a lower capacity, the UTM-E Series can be considered. With this product, load tests can be carried out in a range of 2 to 300 KN. It should be noted that this model has a double test space so that different tests can be performed without having to reconfigure the machine.

The benchtop testing machine

In some contexts, it may be useful to have a benchtop testing machine such as the UTM-D series. This product developed with the latest technology offers the opportunity to perform tensile, bending, flexural and compression testing. The UTM-D series is based on an electromechanical drive mechanism, the frame is developed in a single-column version for loads up to 5 KN or double-column version if tensile tests are to be carried out at higher loads from 5 KN up to 20 KN. The motor used is always of brushless technology with a double test space with the traction being carried out in the lowest area and the compression test in the highest. A computerised control system is always present and it is extremely simple to proceed with the replacement of the various accessories to optimise the test execution. Among other things, the weight of the frame is quite low because the one with a single column is 120 kg while the one with a double column is 300 kg.

Speaking of testing accessories, there are several options available for those who wish to use the company’s various machines, starting with the specimen marking-off machine. The model has been developed in two different versions, namely the manual and the motorised version, which proves to be very useful especially if a large number of samples have to be processed. In addition, the company also supplies strain gauges, which are of course suitable for all kinds of samples and specimens, and a set of accessories for carrying out tensile tests on a wide range of screws and bolts in order to obtain important feedback on these types of items.