Innovation and versatility in material testing

Strain measurement is a crucial aspect in material testing. Often, the physical properties of a material are represented by a stress-strain curve, a kind of “signature” that allows us to characterize the material’s behavior. This measurement is fundamental not only for classifying materials but also for predicting how they will behave during processing or in their final use. The tools that make this measurement possible are called strain gauges.

Strain measurement is a complex and challenging operation.

CERMAC offers a wide range of solutions for strain measurement to meet these challenges. Here are some of their main products:

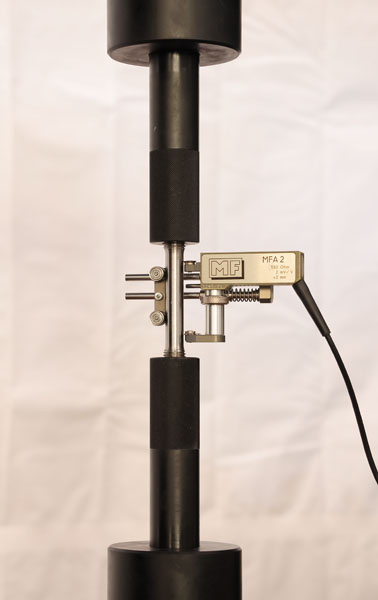

Clip-on extensometer: This type of extensometer is applied directly to the specimen under tension. It is fitted with a high-precision transducer to measure small strains. It is ideal for measuring elongations on flat, round, and wire specimens. However, it is important to know that it must be removed before the specimen breaks. It is also essential that the extensometer does not affect the material’s behavior in the test, especially in particularly delicate specimens where physical contact could cause damage or premature failures and disturb the specimen’s behavior, distorting the measurements.

Maintaining a balance between weight and precision is a significant challenge.

Coaxial extensometer: This extensometer must be positioned before the specimen is inserted between the grips of the testing machine. Thanks to its telescopic tubular structure, it can be used until the specimen breaks. It is particularly suitable for measuring elongations on strands, ropes, and braids made of steel or other materials. Coaxial extensometers must withstand the shocks caused by the failure of the specimens during testing. Their robustness is crucial to ensure reliable measurements, and they must be able to remain fixed even when the specimen undergoes significant changes in its section due to necking.

High-Temperature extensometer: This extensometer is designed for high-temperature tensile tests, with temperatures up to 1400°C. It measures elongation through two arms made of material suitable for high temperatures. Its structure allows for easy handling for the insertion of the arms into the furnace of the test apparatus. This type of extensometer operates in extreme environments and conditions and requires adequate caution during its use due to its fragility.

Automatic extensometer: This motorized device automates the operations of handling and positioning the extensometer, in addition to closing and opening the measuring arms. It reduces human intervention during tests, allowing for greater efficiency. It is suitable for measuring elongations up to the breakage of the specimen. This equipment, which needs to be mechanically integrated into the test machine, can sometimes prove to be delicate due to the stresses at the specimen’s breakage.

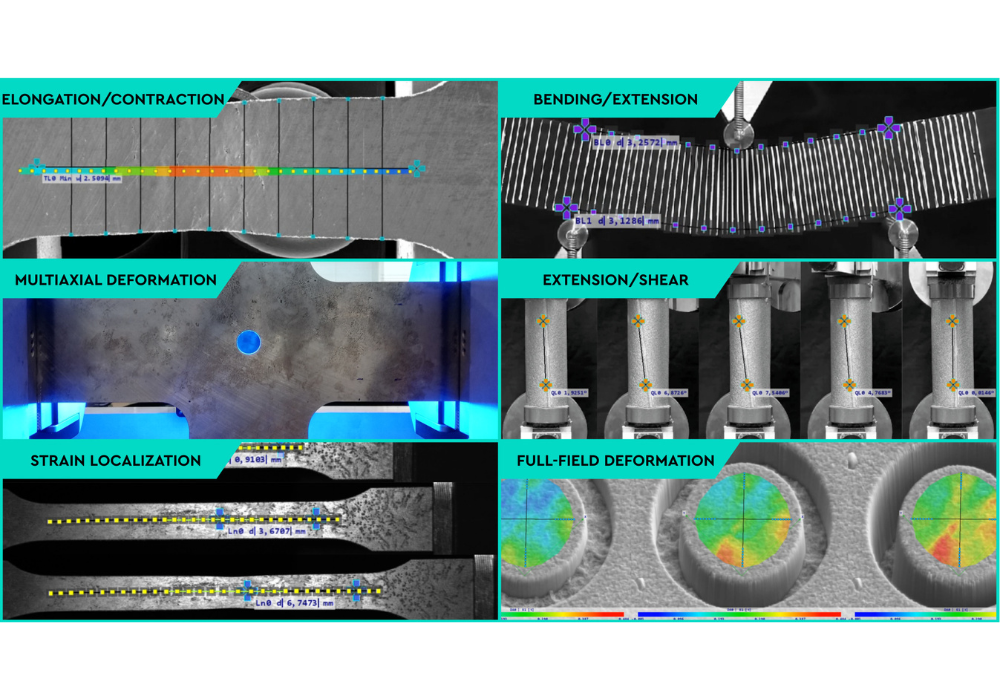

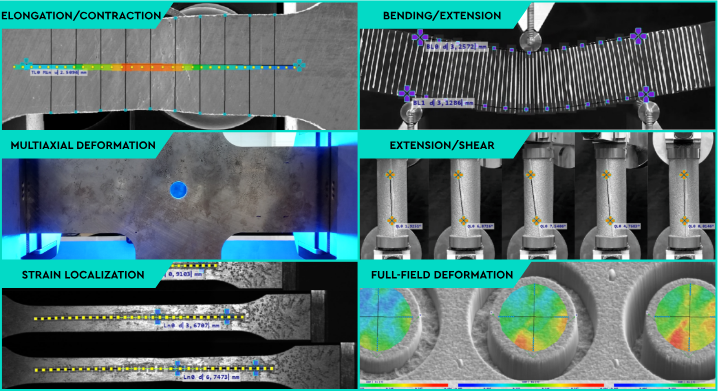

Video extensometer: This type of extensometer can measure the strains of the specimen under tension without the need to apply markings or references. It uses a video camera and Digital Image Correlation (DIC) technology to perform these measurements, also allowing for the analysis of strains. It is suitable for a wide range of materials, including those on which a traditional strain gauge cannot be placed.

All the extensometer models offered by CERMAC integrate perfectly with Testing software, allowing for the synchronized acquisition of all measurements, including load and strain, without the need for external hardware interfaces.

The M Series Video extensometer developed by X-Sight, in collaboration with CERMAC, uses advanced technologies based on Digital Image Correlation (DIC) to provide precise strain measurements. Its operation is fully integrated with Testing By CERMAC software, eliminating the need for external hardware interfaces. The ease of use and numerous software functions make the M Series Video Extensometer suitable for multiple applications in tensile testing on a wide range of materials.

The M Series extensometer can measure both axial and radial deformations simultaneously without the need for markings on the specimens. This versatility makes it suitable for measurements on a wide range of materials, including FRP, FRCM, CRM, FRC, geonets, geogrids, fabrics, and many others. Being mechanically unconnected to the specimen allows for very accurate measurements even in critical conditions.

The special model named HT is also suitable for high-temperature measurements up to 1400°C.

The M Series Video extensometer can acquire data at high speed, up to 200 points per second, allowing for precise and real-time monitoring of strains during tests. Its connection to the PC via a high-speed USB 3.0 port and interfacing with Alpha software further simplify the data acquisition and analysis process.

Alpha software offers a range of modular functions, including the ability to preset different methods, measure multiple strains simultaneously, and conduct guided calibration procedures. Thanks to Digital Image Correlation (DIC), it is possible to measure elongation, inclination, torsion, and many other properties. The DIC-based measurement technique allows for the acquisition of a vast amount of detailed information on the material’s behavior during a test.

While mechanical contact methods and traditional extensometers continue to be used for standardized tests, non-contact measures are gaining ground. Advances in digital electronics are constantly improving the performance of non-contact video extensometers, making them increasingly accepted and reliable. The widespread use of Digital Image Correlation (DIC) to measure strain distributions is paving the way for new testing methods and standardization.

In conclusion, measuring strains in materials is a fundamental aspect of material testing. Traditional extensometers and non-contact video extensometers offer versatile solutions to meet the challenges related to various applications and material types. With continuous technological innovation, the field of material testing is making significant strides towards greater understanding and reliability in material strain measurements, especially in the field of video extensometry.