How does the Charpy pendulum work?

Before understanding what the Charpy Pendulum is, we must ask ourselves what is meant by resilience in mechanical engineering?

The term ‘resilience’ can be applied to different areas of science and is generally related to the concept of strength and adaptation to a hostile situation.

Currently much overused, the term ‘resilience’ actually originated as a term indicative of the behaviour of a subject under considerable stress.

Specifically, resilience in mechanical engineering indicates the capacity of a material to absorb energy, following shocks or considerable loads that could cause it to break.

To precisely identify this requirement, it is necessary to subject the material to a test (called ‘resilience’) that is carried out using the Charpy Pendulum, an instrument that allows a precise value of energy to be applied to a special specimen.

What is the Charpy pendulum?

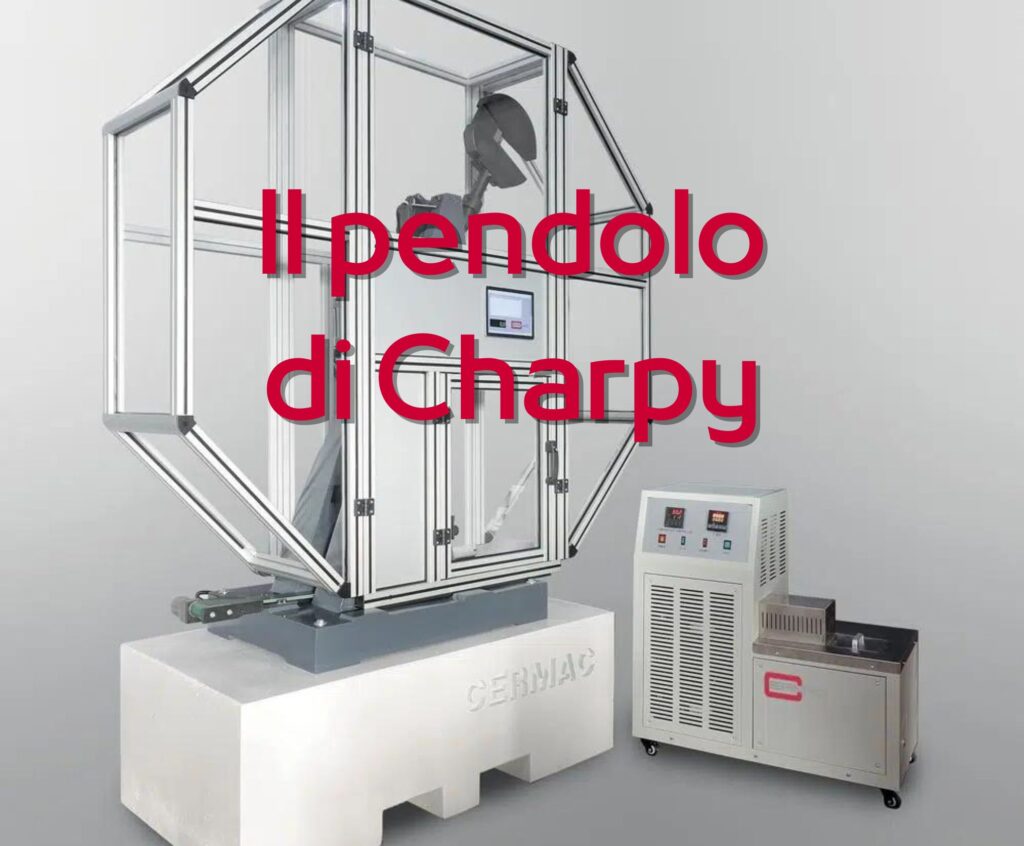

The machine for measuring mechanical resilience is the Charpy Pendulum, a device that measures the energy required to break a given specimen following an impact.

It is a test widely used in industry for its simplicity, speed and low cost, bearing in mind that the degree of resilience is an extremely important factor in clearly indicating the characteristics (and therefore the potential performance) of the material under test.

This instrument can be simply described as a very rigid base in which the specimen is housed and a rod to the end of which a weight with a specific geometry is fixed.

The execution of the test allows metals (and in particular steels) to be classified according to their different degrees of brittleness, which is the fundamental condition in the choice of materials for the construction of mechanical parts of different kinds.

The resilience test carried out using the Charpy Pendulum also allows you to quantify the lateral expansion of the metal (following impact) and the appearance of the fracture zone (which may be more or less extensive).

How is the resilience test performed?

The Charpy Pendulum has been designed to simplify its operation as much as possible, as such tests must be performed frequently and very quickly.

The test consists of raising the free end of the hammer to a certain height (indicated with “H”) and then letting it fall due to gravity.

Following its pendulum trajectory, the free end hits a specific test tube, continuing its rotational movement up to a height (denoted by ‘h’), which is obviously less than H.

The work used to break the specimen is given by the difference between initial energy (falling height) and final energy (rising height).

The instrument is able to work out specific formulae that allow the intrinsic characteristics of the materials tested to be established with extreme precision, in order to provide safe and reliable information on their use.

Cermac is a leading company in the production of materials testing machines that has been a consolidated reference point for almost 30 years.

Its wide range of testing equipment has now also become a point of reference for the production of Resilience Machine, meeting the required certifications.

Cermac therefore confirms itself as the ideal partner for customers who, in addition to products meeting high quality standards, are looking for flexible, innovative suppliers who are always on the ball.