Tensile Strength

Tensile strength is a fundamental parameter of the mechanical properties of materials and identifies the ability of a material to resist tension before breaking. This characteristic is important for materials engineering, for the design of mechanical components and for ensuring the safety and reliability of products in different sectors.

Characteristics and importance

Tensile strength refers to the maximum tension a material can withstand while being tensioned before it begins to deform or break. It is commonly measured in megapascals (MPa) or pounds per square inch (psi).

Application Sectors

- Aerospace: material selection for critical components subject to high stresses.

- Automotive: optimisation of metal alloys for chassis and bodywork.

- Civil engineering: strength assessment of steel, concrete and composite materials.

-

Medical devices: design of strong and durable implants and instruments.

Testing methodologies

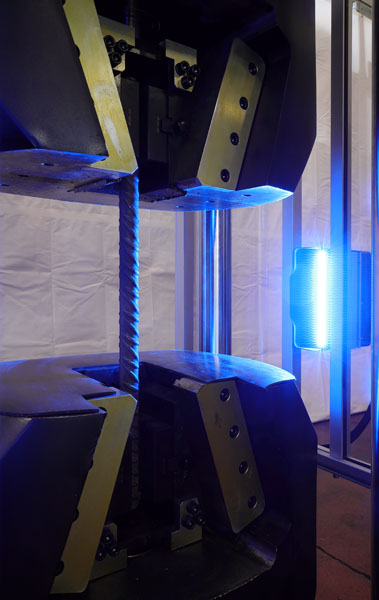

Sample preparation

Accurate sample preparation is essential to obtain reliable results. Samples must be manufactured to precise specifications, with attention to geometry and dimensions to ensure uniformity during testing.

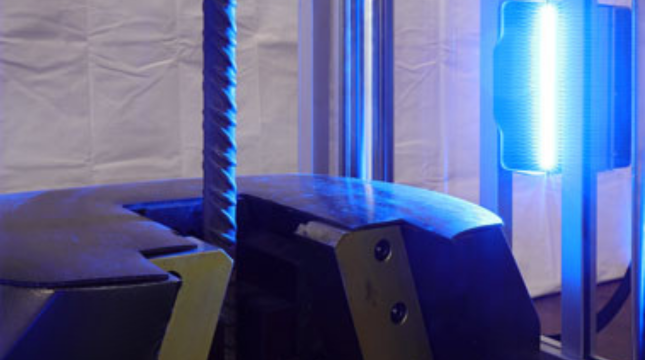

Testing procedures

Tensile tests are performed using universal testing machines, which apply a tensile force to the sample until it breaks. During the test, the applied force and elongation of the material is recorded, allowing the tensile strength to be calculated.

Interpretation of results

The results of the tensile test are represented graphically in a stress-strain diagram, which shows the relationship between the applied force and the elongation of the material. The initial slope of this graph is known as the modulus of elasticity, which indicates the stiffness of the material.

Breaking load

The breaking load represents the critical point at which a material under tension yields and breaks. This measure is fundamental to understanding the maximum strength a material can offer before structural failure, and is closely related to the tensile strength discussed above.

Definition and importance

Breaking strength is defined as the maximum force applied to a material before failure occurs. This value is of primary importance in the design of mechanical components and structures, as it provides a clear indication of the performance limits of materials under stress.

Calculation of breaking load

The breaking load is calculated by analysing the maximum point reached on the stress-strain curve before the specimen breaks. This value is crucial for engineers and designers to ensure that the chosen materials can withstand the expected operating forces during the life of the product without exceeding safety limits.

Practical Applications

- Structural Design: In the construction industry, the tensile strength of structural steels determines the maximum load that beams, columns and other structural elements can support.

- Automotive Industry: Material selection for critical components, such as the axle or chassis, requires precise knowledge of the breaking load to ensure safety under extreme conditions.

- Aerospace: The strength and tensile strength of composite materials used in aerospace are critical to the safety and efficiency of aircraft.